State-of-the-art press line for CLT

With this radio frequency press from Kallesoe Machinery, you will get the most efficient machinery for CLT production on the market.

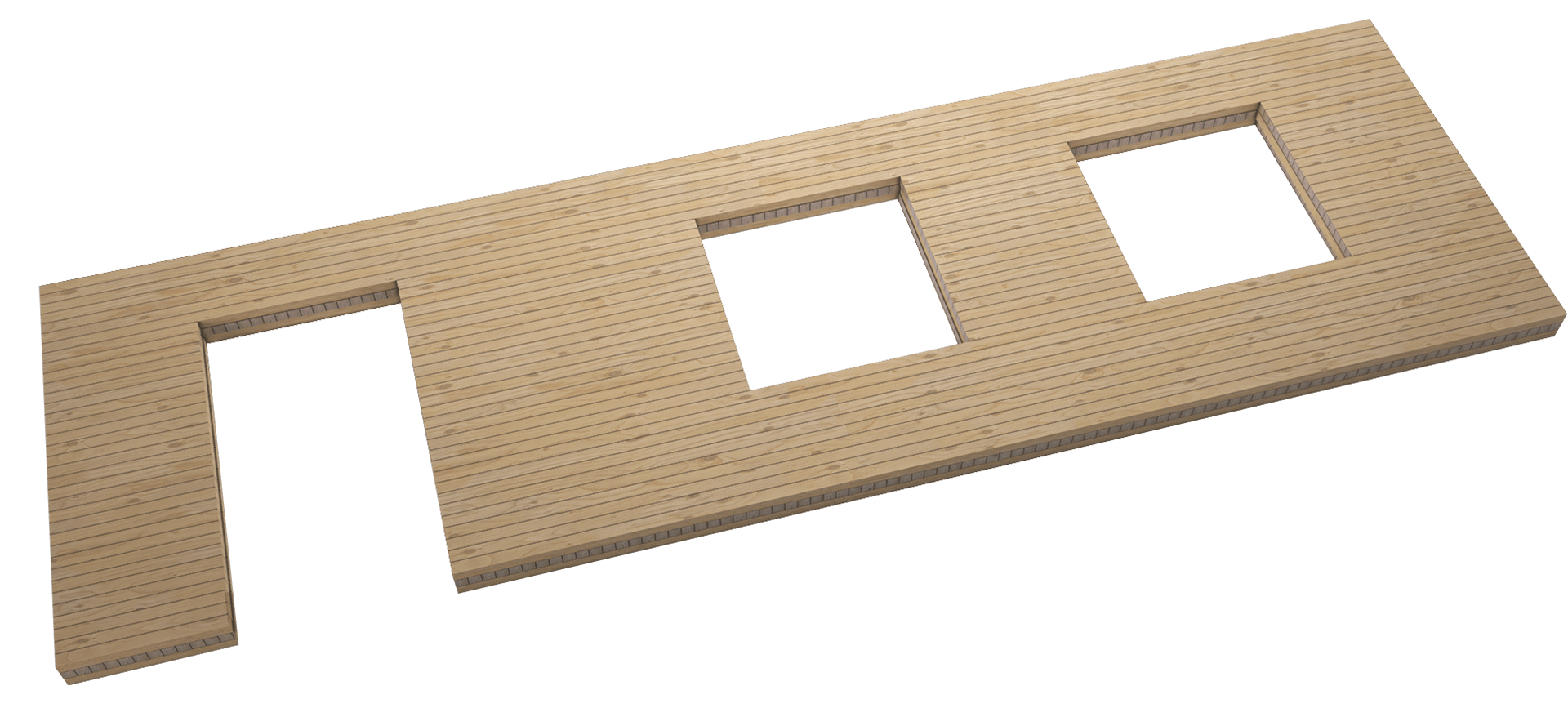

The press is a highly efficient production unit with high capacity and very short pressing times. To save costs, it is possible to leave out wood and glue where door and window openings are intended to be.

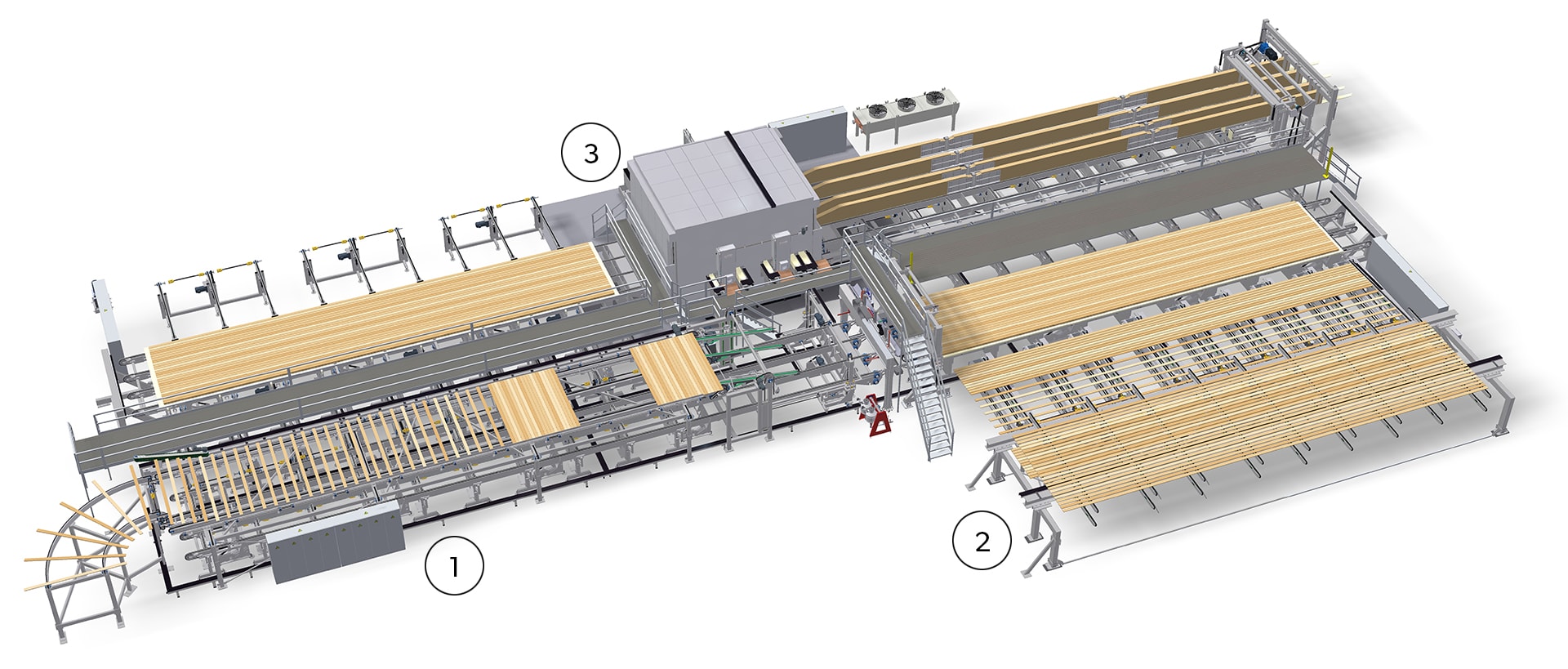

The CLT press line in the illustration handles elements up to 20-meter-long and 3,5-meter-wide and we custom design every line to the specific demands of the customer.

Read more about radio frequency technology and the advantages of using this technology.

1

Before the CLT element enters the press, it is shaped and laid up on a plastic board that transports the wood during the entire lay-up and press process. Each layer consists of pieces of lamstock that are running lengthwise or crosswise. Glue is applied between each layer and the lamstock in each layer can be edge glued as well.

A CLT element consists of at least three layers – typically with an even number of layers running lengthwise with layers running crosswise in between them. It is possible to start or finish an element with a layer of lamstock running crosswise if wall elements with vertical pieces of lamstock is wanted.

2

The layers of lamstock are placed on the plastic board in the lay-up system.

A set of arms carries the pieces of lamstock running lengthwise to the plastic board. When the arms are pulled back, the lamstock glides into place. The new layer is adjusted to make sure it is lying correctly.

The plastic board is transported under the face gluing system and on to the lay-up system for the lamstock running crosswise. When the plastic board reverses, the lay-up system runs with the same speed to place the cross lamstock on the length layer lamstock. This process of alternating between a length-layer, glue, and a cross-layer is repeated until the desired number of layers is reached.

3

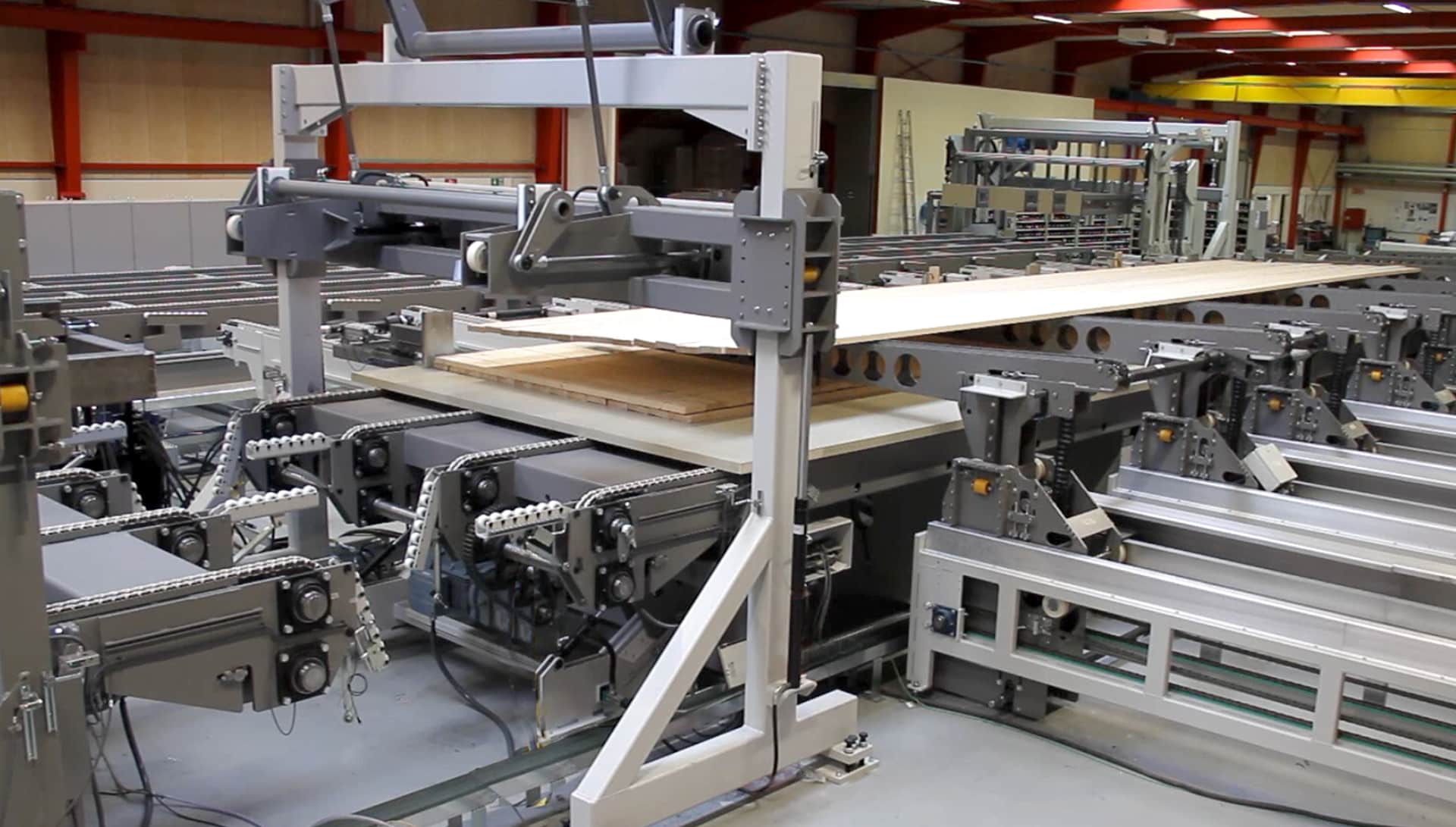

When the prepared CLT element is brought into the press, the lamstock needs to be pushed together. A pushing unit ahead of the press pushes the cross running lamstock together before the hydraulic cylinders of the press transfers the necessary laminating pressure from the top and the sides. Strong glulam beams are lowered onto the part of the CLT element, that is protruding and thereby stopping the element from curving upwards.

When the press cycle is done, the CLT element is pushed forward to further processing. The empty plastic board is then ready for at new lay-up.

The press time depends on the type of glue, the thickness of the lamstock, and the number of layers in the element.

Specifications

This press has a press length of 4 meters and a press width of 3,5 meters. It can continually press up to 20-meter-long elements – the length of the CLT element only depends on the length of the inlet and outlet table.

The minimum pressing height is 60 mm. For panels under 60 mm we refer to our press lines for multi-layer panels.

The minimum and maximum length, width and height are listed below – but we can make a press line that specifically fits your products and production needs.

Length: 4,000 – 20,000 mm (13 ft 1 in – 65 ft 7 in)

Width: 2,200 – 3,500 mm (7 ft 2 in – 11.5 ft)

Height: 60 – 400 mm (2.4 – 15 3/4 in)

“One of the reasons we went with Kallesoe Machinery is because they have been so accurate in their timelines, they do quality work, precision work and their ability to deliver a high-end product is something we feel very confident in”

“Kallesoe took the necessary time and adapted the machines to our individual needs.”

“We have been in this business for 82 years. Kallesoe is by far the best and most professional supplier we have ever done business with. They are so easy to work with, and they know their products and business area. It has been a pleasure. It is important to go the extra mile to make sure that the customer is satisfied – and they do that at Kallesoe.”

References in the CLT industry