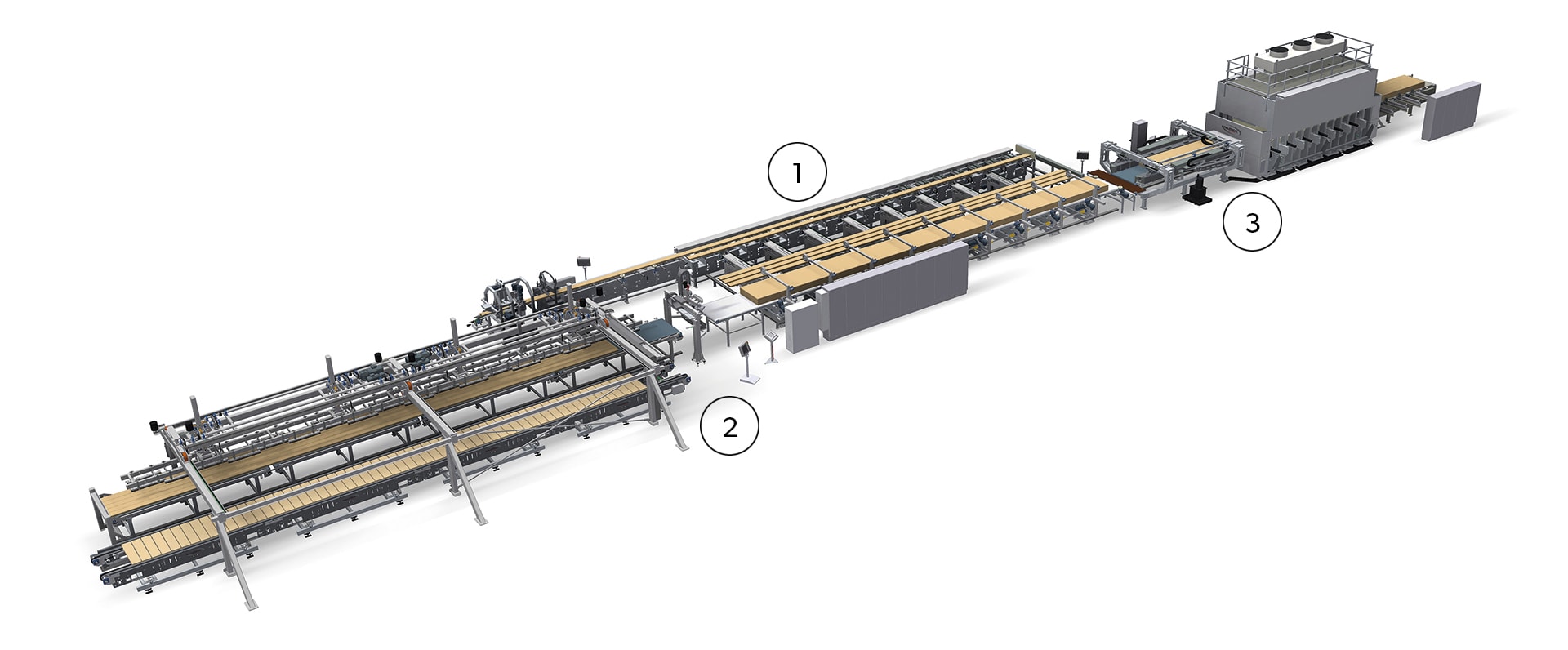

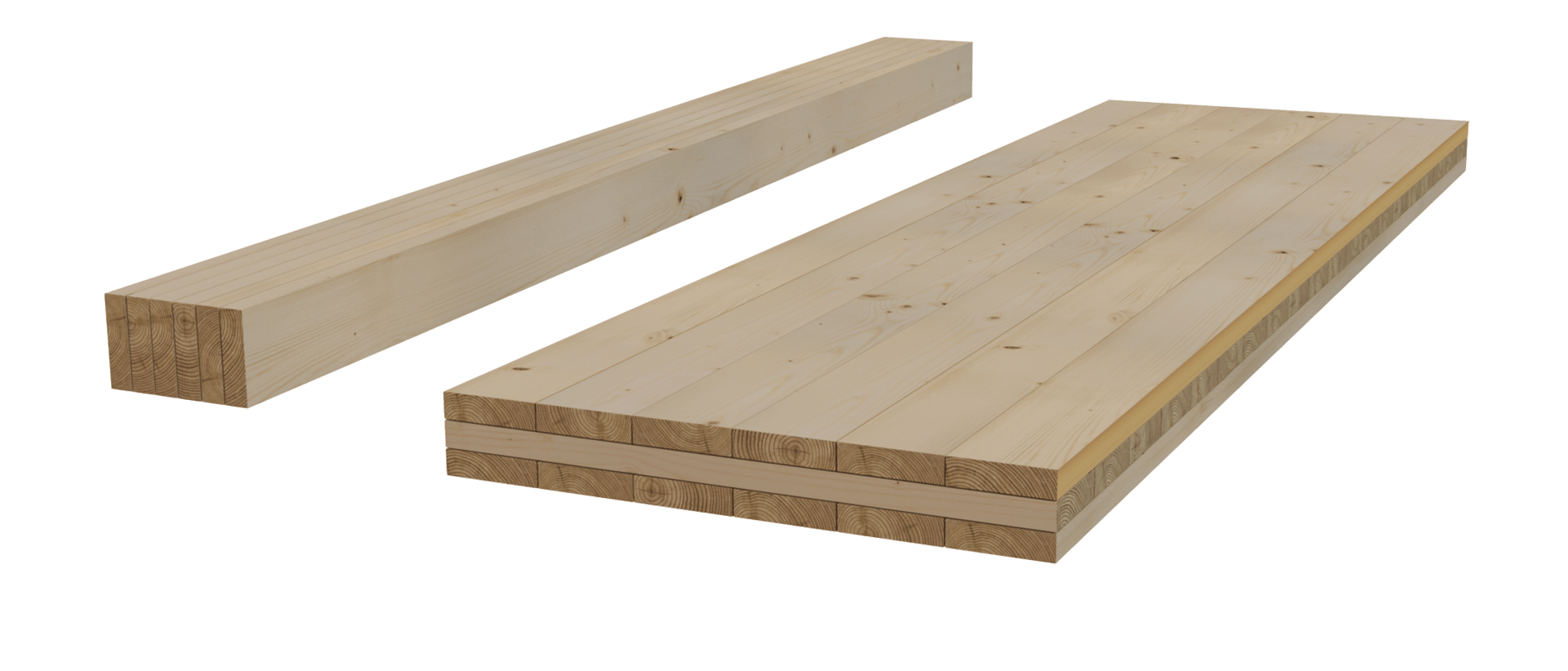

Combi press line for CLT and Glulam production

This efficient radio frequency production line with a special lay-up system has the option to manufacture two different kinds of products in the same system: CLT elements and glulam beams (GLT). You will get increased capacity and flexibility without needing extra space.

The press uses radio frequency technology to cure the glue, which has the great advantage of short press cycles and thereby an increased capacity – the ideal line for a just-in-time production.

Read more about the radio frequency technology and the advantages of radio frequency here.

We design every production line to fit our customers’ products and production needs.

1

CLT

When manufacturing CLT elements, glue can be applied to the edge of the longitudinal lamstock. The lamstock are cross conveyed to a temporary collection unit, where they are joined together and lifted onto a belt conveyor to add more layers.

The charge is reversed under the vacuum gantry where the cross lamstock are positioned. Glue is applied between each layer.

The CLT element can be completed with a second layer of longitudinal lamellas, or the process can be repeated until the desired number of layers has been reached.

2

Glulam beams

In the production of glulam beams a layer of glue is applied from above with a face gluing unit. The glued pieces of lamstock are cross conveyed one by one, turned 90º, joined and fixated in a charge.

Following this, the charge is loaded onto a belt conveyor which feeds it into the press.

3

CLT and Glulam

The completed product charge is fed into the radio frequency press where it is pressed from the side and the top and the radio frequency energy is added for a rapid curing.

Read more about the radio frequency technology here.

The illustrated Combi press line handles up to 27-meter-long elements – but the machinery can be designed and adapted to your production needs and requests.

Specifications

The minimum and maximum length, width and height are listed below – but we can make a press line that specifically fits your products and production needs.

Glulam

Length: 3,000 – 27,000 mm (9 ft 10 in – 88 ft 6 in)

Width: 1,250 mm (4 ft 1 in)

Height: 60 – 290 mm (2.4 – 12 in)

CLT

Length: 6,000 – 27,000 mm (19 ft 8 in – 88 ft 6 in)

Width: 1,150 – 1,250 mm (3 ft 9 in – 4 ft 1 in)

Height: 60 – 290 mm (2.4 – 12 in)

More information

“Kallesoe took the necessary time and adapted the machines to our individual needs.”

“One of the reasons we went with Kallesoe Machinery is because they have been so accurate in their timelines, they do quality work, precision work and their ability to deliver a high-end product is something we feel very confident in”

“We again opted for solutions by Kallesoe because of the high flexibility”

„Kallesoe were the only plant suppliers who kept what they had promised. Set up, turn on, produce“

“We have been in this business for 82 years. Kallesoe is by far the best and most professional supplier we have ever done business with. They are so easy to work with, and they know their products and business area. It has been a pleasure. It is important to go the extra mile to make sure that the customer is satisfied – and they do that at Kallesoe.”

“The changeover possibilities of the press were crucial to us since we deliver to markets that demand different dimensions of the products.”

“Kallesoe has delivered as promised and supported us in the best possible way”

“The technology was very impressive. We are convinced that it is much better than other technologies on the market. It is all about flexibility and speed.”

„The line runs as it should – smoothly. The performance lives up to what was promised. We would buy the same machine all over again.“

”The collaboration with Kallesoe was really good. The machinery is performing to our full satisfaction.”

“The Danes were really well prepared, and when it comes to machinery they are one of our most competent partners.”

References in the CLT industry