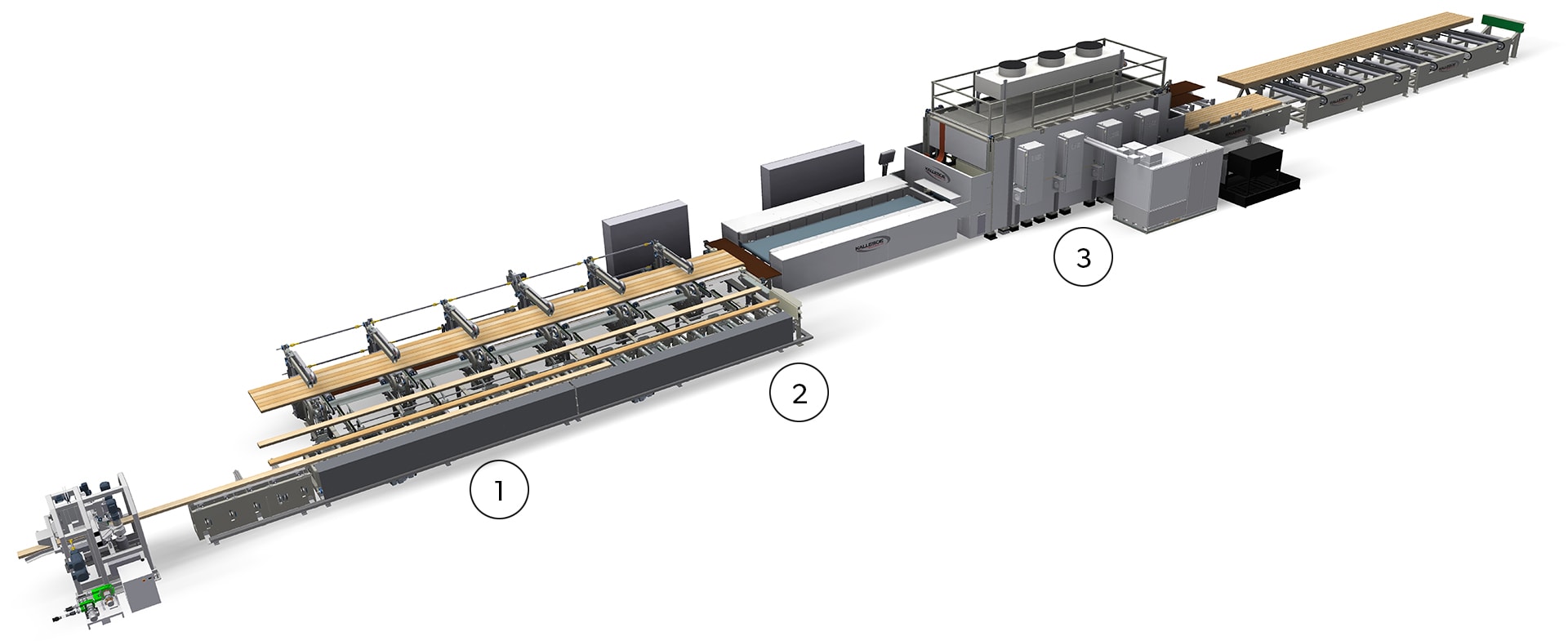

Duo XL press line for production of boards and large glulam beams

This Duo XL press line gives you a unique opportunity to produce solid wood boards and large glulam beams in the same press line.

The duo press line is developed with a double glue system that can be added to the top and the side of the lamstock – which means that it can produce two products: boards and beams.

This allows for a wider range of products and an increased capacity without needing extra space.

The press uses radio frequency energy which means that the glue cures quickly, making the press cycle shorter as well while increasing the capacity.

Read more about the advantages of using radio frequency technology.

1

Solid wood board production

In the board production the glue is added to the edge of the lamstock by a glue roller.

The lamstock runs on a conveyor to the cross handler, that leads the lamstock to the inlet table. On the inlet table the lamstock are gathered and kept together until the batch is ready to go into the press.

2

Glulam production

The glue is added to the lamstock. The lamstock is then transported on a roller conveyor to the raise/up right/standing system.

The glued lamstock is then stood up and gathered on a conveyor belt where they efficiently are kept in place while more lamstock are added

3

The press

The batch is led into the press. The press uses side and top pressure to make sure that the boards and the beams are uniform and of high quality.

The radio frequency technology makes the glue cure quickly and efficiently.

Specifications

Minimum and maximum lenght, width and height are listed below – but we can make a press line that specifically fits your products and production needs.

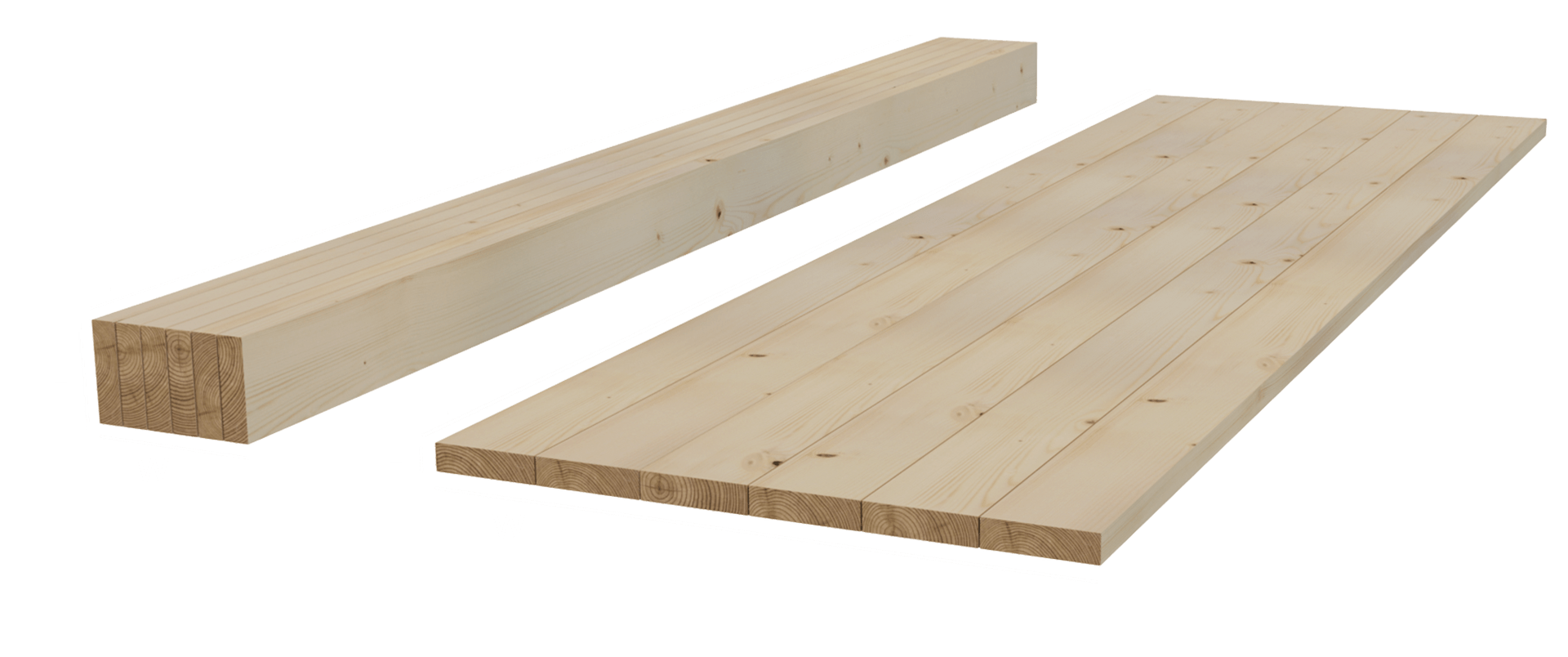

Solid wood board

Length: 6,000 – 27,000 mm (19 ft 8 in – 88 ft 7 in)

Width: 840 – 1,280 mm (2 ft 9 in – 4 ft 2 in)

Heigth: 30 – 150 mm (1,2 – 6 in)

Glulam beam

Length: 3,000 – 27,000 mm (9 ft 10 in – 88 ft 7 in)

Width: 840 – 1,280 mm (2 ft 9 in – 4 ft 2 in)

Heigth: 60 – 290 mm (2.4 – 11 in)

More information

„Kallesoe were the only plant suppliers who kept what they had promised. Set up, turn on, produce“

“The technology was very impressive. We are convinced that it is much better than other technologies on the market. It is all about flexibility and speed.”

“The lead equipment supplier, Kallesoe Machinery, are delivering equipment exactly to the day they promised two years ago, when we signed the contract with them. We couldn’t ask for a better partner to be working with.”

References in the solid wood board industry