CW press for boards made from conical wane edge timber

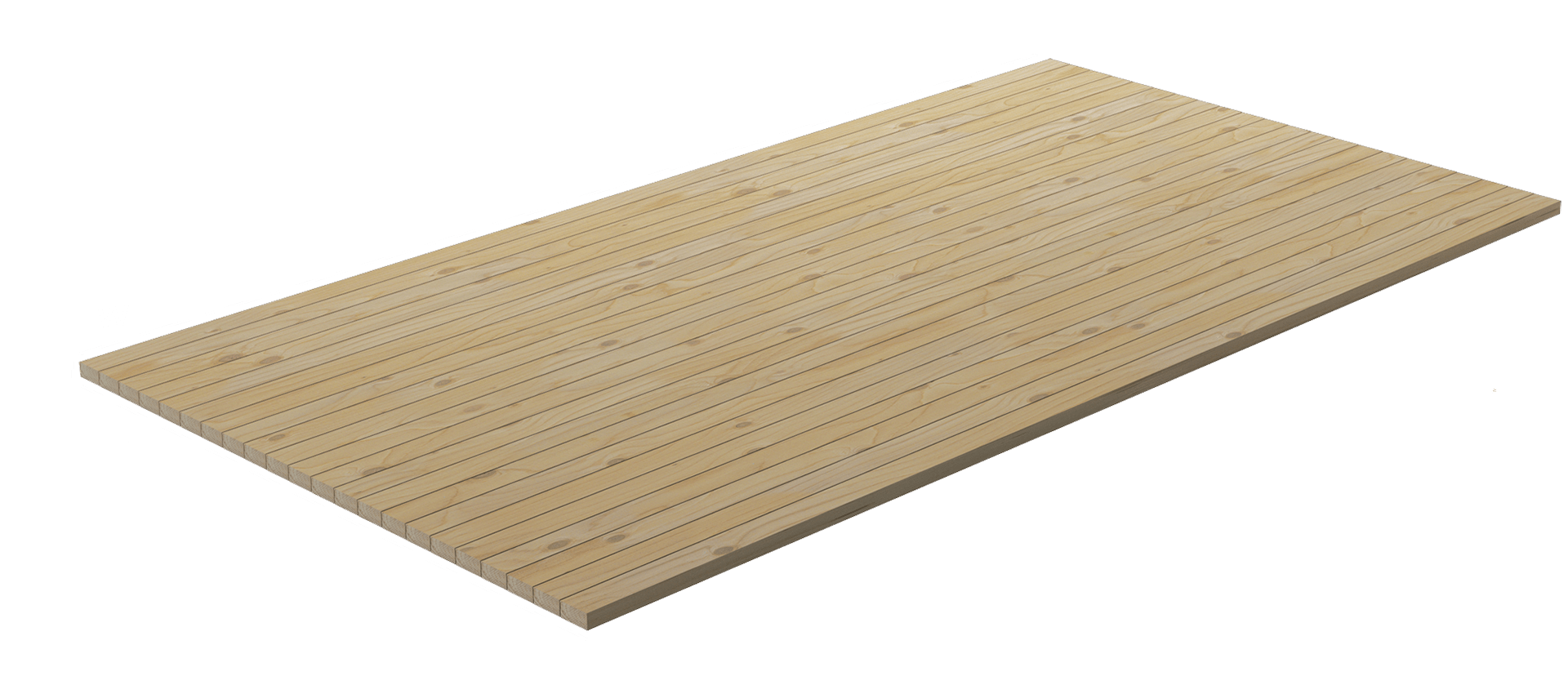

Our CW press system allows you to make up to 10 % better use of your side boards by maintaining their potential conical shape and wane edges.

When the most regular parts of a log have been refined and as an example used as construction material or furniture production, you are left with the parts closest to the bark. These parts often have wane edges and can be conical and are therefore not easily used in conventional production systems.

The CW press changes this so that your wane timber has a higher value. The unique technology in the system automatically analyses the wane timber. It is measured, sorted, turned, glued, and pressed together to a continuous board that can be sawn into the needed dimensions.

This product has a wide range of uses – including as the middle layer in CLT elements.

You get an extremely environmentally friendly board that uses the full potential of the log.

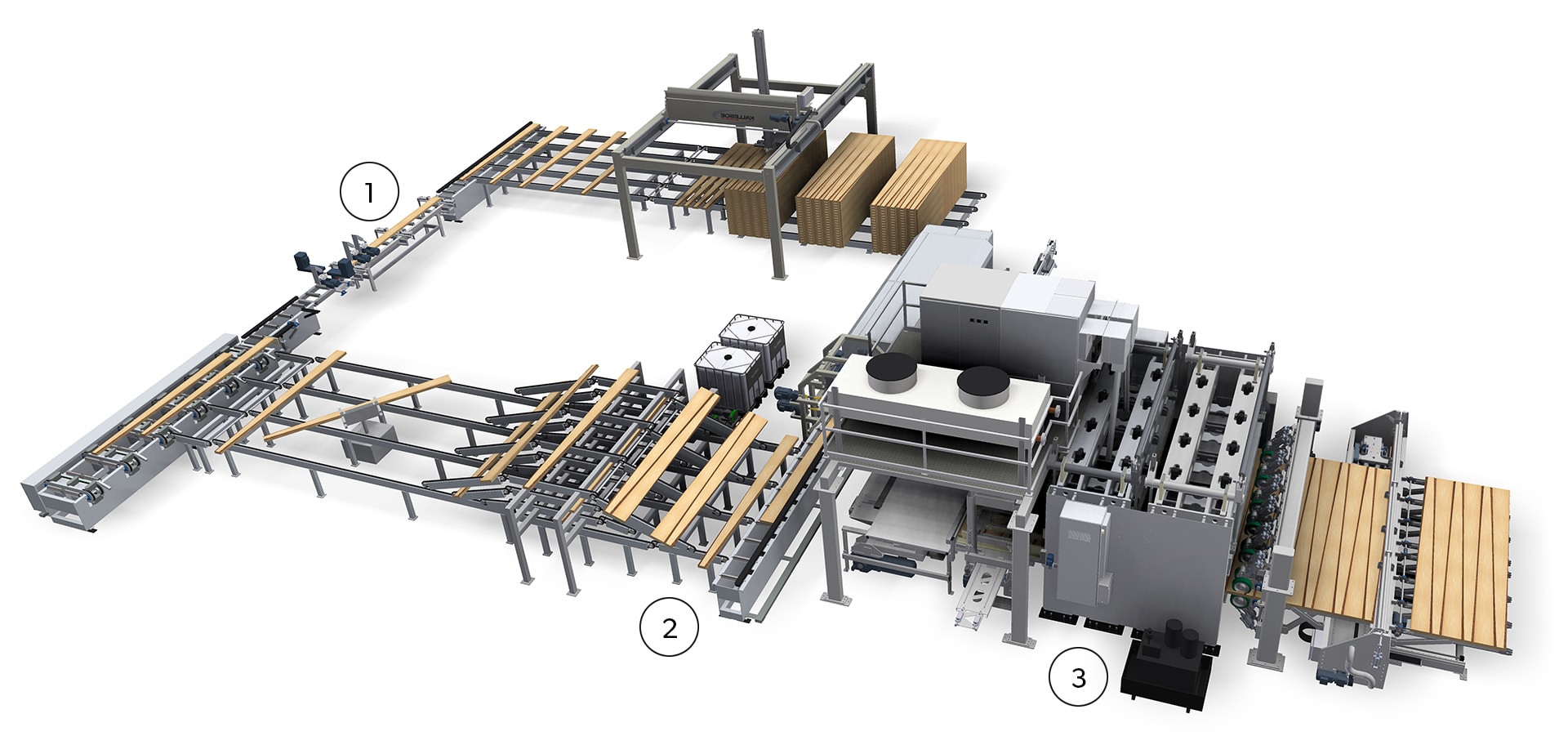

1

The system is able to measure the angles of the wane timber and decide if the timber should be turned – in order to get an approximately straight board in the end.

The timber is sorted into four levels according to their conical shape.

The system calculates in which order the sorted timber is transported to the glue applicator.

2

Glue is applied to the edge of the wane timber.

Leaving the glue applicator, the timber is cross-conveyed into a magazine in which they are gathered in a charge.

When the magazine is full, the timber is led to a feeding table in front of the press.

3

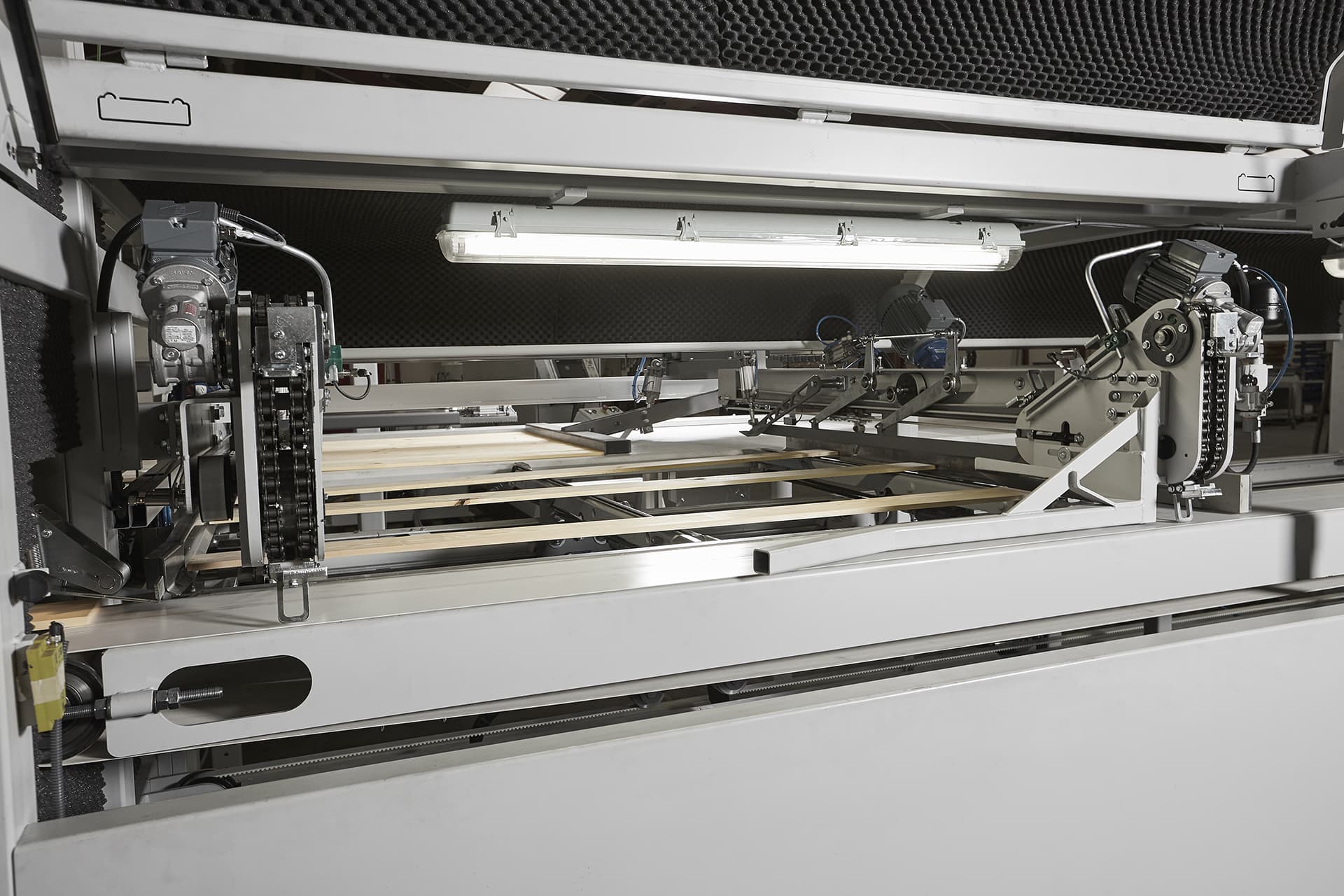

The glued lamellas are fed into the fully automatic press which consists of two parts: a radio frequency (HF) unit and a hot press unit.

The radio frequency (HF) energy targets the moisture in the glue which quickly heats up and cures from the middle.

The hot press section cures the surface of the board, and the process results in a fully cured board in a very brief press cycle.

Behind the press, saws can be installed enabling the cutting of the endless board into smaller units – both in longitudinal and transverse directions.

Specifications

The minimum and maximum lenght, width and height are listed below – but we can make a press line that specifically fits your products and production needs.

The width depends on the subsequent handling equipment.

Width: 400 – 6,000 mm (1 ft 3 in – 19 ft 8 in)

Length: 60 – ∞ mm (2,4 in – ∞)

Heigth: 10 – 45 mm (0,4 – 1,8 in)

More information

“The technology was very impressive. We are convinced that it is much better than other technologies on the market. It is all about flexibility and speed.”

“Kallesoe took the necessary time and adapted the machines to our individual needs.”

„The line runs as it should – smoothly. The performance lives up to what was promised. We would buy the same machine all over again.“

References in the solid wood board industry