Custom-made solutions for production of multi-layer panels

It is crucial to us that you get exactly the right system solution for your production of multi-layer panels. With decades of experience behind us we are dedicated to find the right system solution in close collaboration with you and your business. Our machine solutions are adaptable to your production needs and with the latest technology you will get the highest capacity in premium quality.

Our experienced staff, innovative technology, and flexible machine solutions will ensure, you get the right turnkey solution.

You know the need, together we find the solution.

Find examples of our production of multi-layer panels

Your solution is made uniquely for you

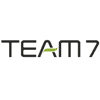

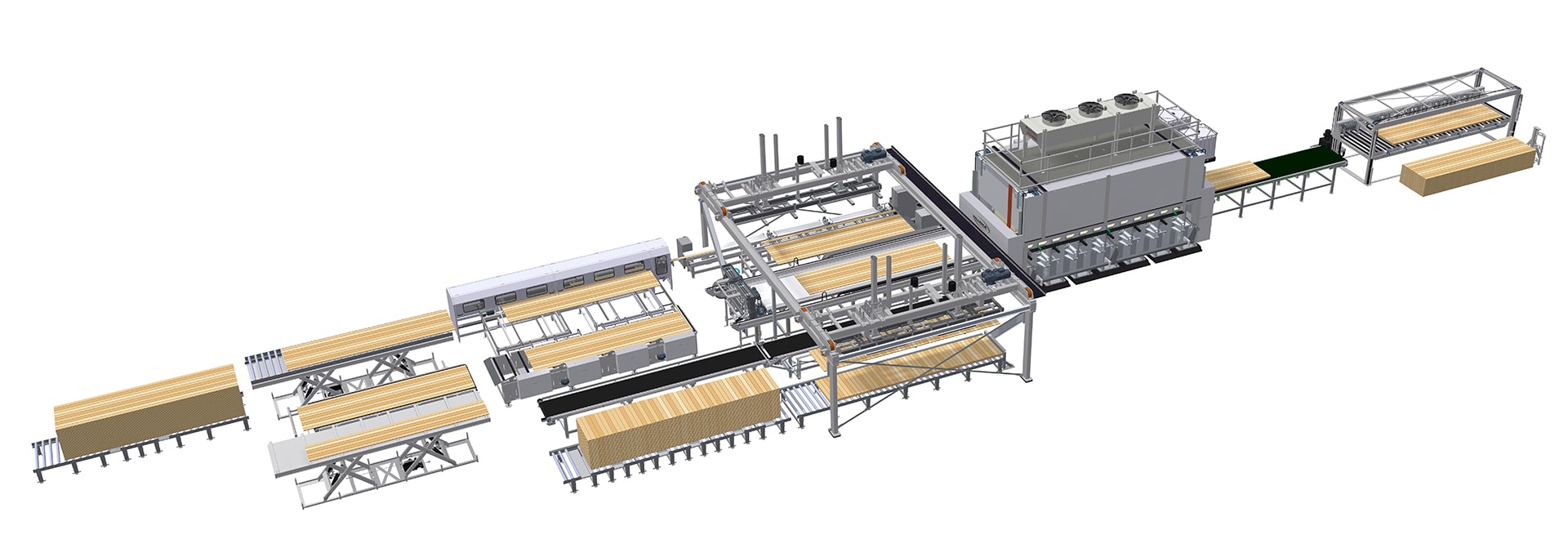

Multi-layer panels press system - RF press

Solution for manufacturing multi-layer panels to be used for construction purposes or as panels for cladding and where strength and stability is needed.

This layout operates with a manual lamstock infeed that optionally can be automated. Long pieces of lamstock are fed-in as single lamellas, and the outer lamstock layer can optionally be edge glued to obtain a good visual finish. The crosswise layer is fed in as single pieces of lamstock or as pre-made panels. A vacuum gantry is used to bring the layers in a center position in front of the press.

After each movement, the layer is surface glued by a full width travelling glue applicator and the complete billet is transported to the RF-press.

The finished panels are subsequently stacked before transfer to further processing.

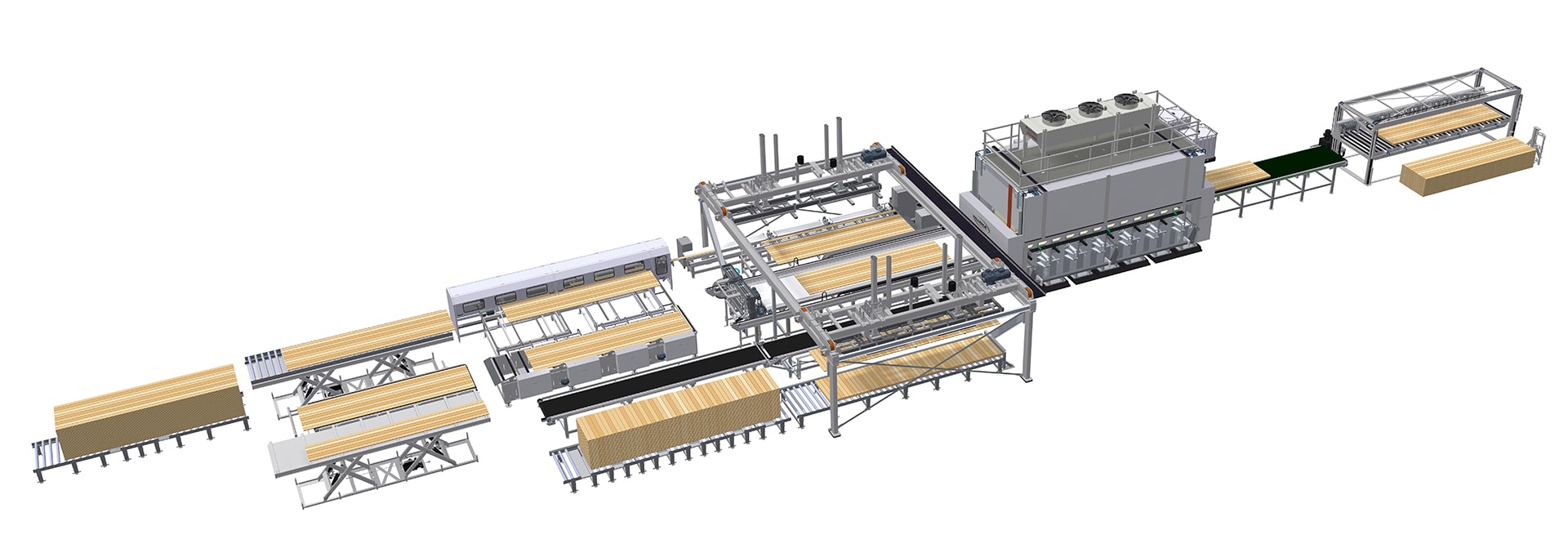

Multi-layer panels press system – hot press

Solution for manufacturing multi-layer panels to be used for construction purposes or as panels for cladding and where strength and stability is needed. This press system is very cost-effective.

The layout operates with a manual lamstock infeed that optionally can be automated. Long pieces of lamstock are fed-in as single lamellas, and the outer lamstock layer can optionally be edge glued to obtain a good visual finish. The crosswise layer is fed in as single pieces of lamstock or as pre-made panels. A vacuum gantry is used to bring the layers in a center position in front of the press.

The press is a hot-press using thermo-oil to obtain high temperature to speed up curing. After the press, the system is equipped with a turning device that allows product repairs on both sides before stacking.

“Kallesoe took the necessary time and adapted the machines to our individual needs.”

“One of the reasons we went with Kallesoe Machinery is because they have been so accurate in their timelines, they do quality work, precision work and their ability to deliver a high-end product is something we feel very confident in”

”Kallesoe Machinery is state-of-the-art and absolutely market leader for this type of equipment, so we had to have these machines. They are the tomorrow’s system for the production of glulam beams”

Contact

Let us find the right solution for you

References in the multi-layer panel industry